Electric Contacts

Silver is one of the most conductive metals available, making it an excellent choice for enhancing electrical conductivity in various applications. By adding a silver layer to a surface or material, the electrical resistance is significantly reduced, allowing for more efficient current flow. This is particularly beneficial in industries such as electronics, telecommunications, and energy, where high conductivity is crucial for performance and reliability.

The silver layer creates a thin, conductive coating that can be applied to metals, improving the overall efficiency of electrical connections. Its corrosion resistance also ensures long-lasting performance, making it a cost-effective solution for extending the life of components. Whether used in circuit boards, connectors, or specialized coatings, a silver layer is a proven method to enhance conductivity while maintaining durability and stability.

Induction casting

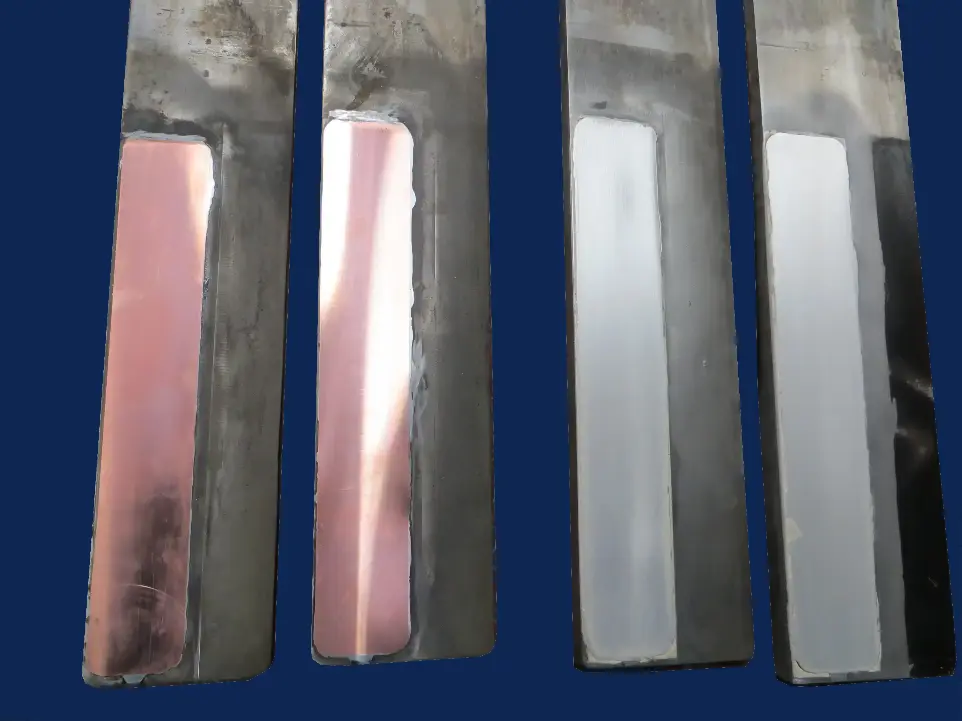

These contact surfaces are engineered for use in aluminum casting with induction technology. Featuring a copper base with silver coatings, they provide exceptional electrical conductivity and heat transfer. The silver-plated contacts minimize resistance and corrosion, ensuring consistent performance in high-temperature environments. These surfaces are designed to optimize the efficiency and lifespan of casting equipment, making them ideal for industrial applications where precision and durability are essential.

Aluminium Anodes

This combination of aluminum, copper, and silver layers enhances the overall performance of the anodes by optimizing both corrosion resistance and electrical conductivity. This setup is useful in systems that require both protection from corrosion (via the aluminum anode) and efficient electrical conductivity (thanks to copper and silver contacts), such as in high-voltage applications or power transmission systems.

Silver-plated axle ends like the one in the image are common in industries that rely on high-performance electrical components. This includes sectors such as:

- Automotive: For electric vehicle motors and alternators.

- Energy: In generators and turbines that depend on efficient electrical conductivity.

- Manufacturing: For specialized machinery that uses electromagnetic induction for heating, processing, or power generation.

At Meta Croom, we specialize in applying silver coatings to critical components to enhance their performance, ensuring they meet the rigorous demands of modern industries. Whether you require conductivity improvements or long-lasting protection for your industrial parts, silver plating offers the ultimate solution.